Re-stringing a Fisher microphone boom

Twice, now, I've come across this Fisher boom, and both times it's been

in a state of disrepair, this time it was my turn to bring it back to life,

and I'm sure I'm destined to encounter it again. The boom used to

belong to the ABC in Adelaide, but they gave it to Flinders University,

many years ago, now it's been hired for a production. Today, it's in

the South

Australian Film Corporation's Adelaide Studios at Glenside, in the

smaller television

studio (where this photo was taken of me standing on it).

Peculiarly, neither Film Corp studio has a lighting grid

(just a catwalk above several massive iron girders), nor a prop bay or

workshop. Consequently, rigging and equipment has to be hired in,

at no small expense. And crews end up building and painting sets

in the carpark (getting dust and crap blown onto their wet paint), or in

the studio (spreading dust and fumes). That's the kind of silliness

you expect at a film school, not the state's film studios.

Not having any documentation about how to re-string it, it was a fair

bit of trial and error to work out how the string should go around the

mechanism, but I think I managed it. So, if anybody knows, for sure,

how it ought to be done, I'd appreciate the information. Later on, I

found some brochures for more recent Fisher boom models, which are

almost the same, but no manuals, and there wasn't enough pictures to work

it out, fully. Though it was enough to show that the counterweights

were initially mounted in the wrong places (as seen in these pictures), the

large solid one should be mounted above the rolling section (where you can

easily crush your knuckles between it and the squeezable grip for rotating

and tilting the microphone cradle), the smaller solid one under the back of

the rear of the pole. The third, hollow, counterweight that lets you

insert variable amounts of lead weight inside it, to tune the weight to

suit your microphone and cabling, mounts under the rolling section.

We couldn't work out how it was supposed to slot in (it looks like it has a

catch and a quick release), we had to remove the rear bolt to insert the

counterweight, and replace the bolt to hold it in place. You can see

these weights by my left foot, sitting on the platform, in the photo at the

top of this page.

It is a really vintage model. The J.L. Fisher website has newer

models listed on it, that are similar, but not close enough to be a

good-enough guide to working it out, and even they don't have a close-up

view of how the boom is strung up. The first time I saw this boom, it

was in the corridor between studios at the ABC, in the mid-1980s. And

I'm sure that they had it a lot longer before I saw it, the design looks

1960s/1970s.

NB: All of the small pictures on this page can be

clicked on to see the full-sized versions. The full-sized versions

don't have the highlighting colours drawn over them. I've used the

same colours for the same strings, in all the pictures, so it's easier to

follow where they go. And, I must emphasise, that I know some of the

photos show the boom not set-up correctly. I, eventually,

got it into a workable condition, but not optimal. But didn't have an

opportunity to re-photograph it.

|

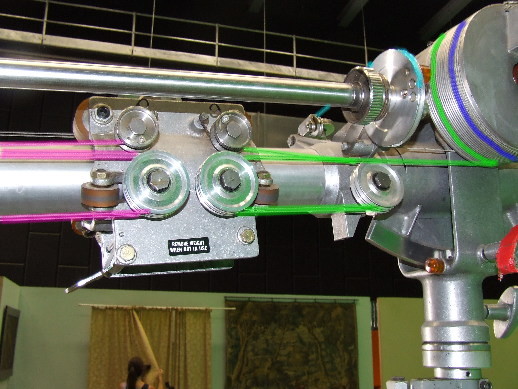

Corrections to this photo: The mike cradle

rotator string is erroneously passing through the mike cable clamp (the

thing with the wingnut). And that clamp has been mounted upside

down. It should hold the mike cable above the control string.

There's a number of mike cable clamps missing, as well (they look like

miniature broomstick clips).

|

Several strings drive the moving parts of the boom arm and mike

cradle, to extend and withdraw the telescoping section of the boom

arm, and adjust the angle of the mike cradle. The drive strings

really are just string, not wire. The mike cradle strings

aren't directly driven by the operator controls; instead, the

controls move a second set pulleys that are pushed against the drive

strings, re-tensionining them, and this moves the mike cradle.

But the strings that move the telescopic boom pole in and out are

directly driven, a crank handle pulls the strings connected to the

pole.

Moving the boom up and down, or left and right, is simply done by

shoving the pole with your arms. It's not perfectly balanced,

and has a tendency to lift up or fall down, depending on how far the

telescopic section is extended. There are moving counterweights

that are supposed to compensate, but they don't quite do the trick,

and considerable effort is required to adjust the boom-arm tilt-angle

at the two extremes of pole length. I'm not sure if this is a

design flaw, or the boom needs further work to configure it

properly.

The platform that you stand on, or sit on the attached seat, can

be raised or lowered (there's some kind of hydraulic system, with a

manual hand pump arm, that doesn't appear to be functional on this

unit). And I beleive the pole that the swinging boom mounts on

top of, will rise or lower, at the same time.

The wheels are chained together, so they can all be steered

together. Or the front two (as seen in this photo), can be

locked into the forward-facing position, and the rear wheel steered

independently. There's a brake on the rear wheel, to stop the

platform rolling away. And cable guards around each wheel, to

push cables out of the way while tracking around the studio, which

can be lifted up for when you need to transport the boom,

elsewhere.

The tyres are soft/squashy pneumatic types, and the whole thing

rocks about while you're on it. It has a resonance that's like

when you're in a small dinghy on a lake.

|

|

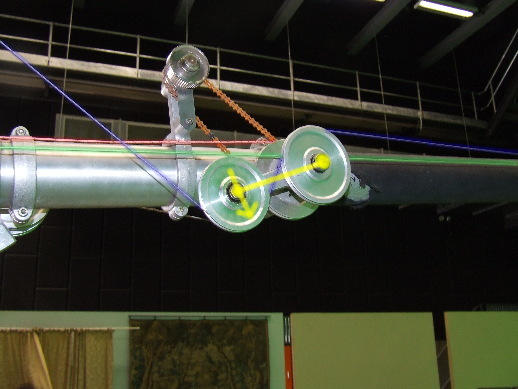

Corrections to this photo: The orange

string is erroneously passing through the mike cable clamp (the thing

with the wingnut). And that clamp has been mounted upside

down. It should hold the mike cable above the control string.

There's a number of mike cable clamps missing, as well (they look like

miniature broomstick clips).

|

Just two strings control the angle the mike is aimed at (tilt and

rotation).

The rotating mike cradle is spring loaded, you wind the cradle

around a few times (clockwise, from the point of view underneath the

cradle) to tension the spring, then let the control string wrap

around it a few times as the spring rotates the cradle back

around. This string (highlighted with orange) passes back along

the boom, through a guide.

There's a pulley missing just right of the rotating mike cradle,

or the control string is simply supposed to pass over the top of the

mike audio cable, in free air. The drive string is being pulled

through what's supposed to be the clamp for the mike audio

cable. On the other side of the boom (hidden on this photo),

there is a a pulley for the tilt string, I would expected there to be

similar pulleys on both sides of the boom pole.

Just underneath the rotating platform are three screws jutting out

at 45 degree angles that allow you to reposition the angle the mike

cradle faces at. Positioning the cradle to face the mike

forward when nobody's holding the panning grip seems to be the right

position), but it's facing backwards in this photo. When the

panning mechanism is operated, it gives about one a half turns of the

rotator, though the panning handle is only easy to operate for about

270° of that. There should be a mike audio cable clip somewhere

on this platform, and there's another on the mike cradle arms, to

hold the cable out of the way of moving parts, and providing enough

slack for the cradle to move, and isolate the the microphone cable

from physically transmitting boom handling noises to the

microphone.

The mike cradle tilt control string (highlighted with blue) passes

through the top of the rotator, around a couple of pulleys, and back

along the outside of the boom, on the side that you can't see in the

photo, although you can see the string held out quite some way from

the pole. This picture shows the tilt cradle facing backwards

(the moving part of it highlighted with yellow), if you pull the tilt

string, the cradle will end up tilting back along the boom pole (as

per the yellow arrows).

|

|

This is half way along the mike boom, it's where the telescoping

section enters the fixed section.

On the left side, behind the pole, is the mike cradle tilt control

string (highlighted with blue), it passes by without going through

any pulleys.

On the right, you can see the mike cradle rotation control string

(highlighted with orange), going over the top of a thin black

pulley. Next to it is a fatter black pulley, where the mike

cable would pass over. The two pulleys spin independently

from each other.

|

|

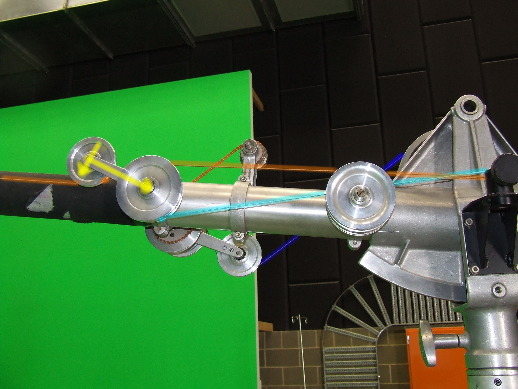

Corrections to this photo: The large

counterweight seen hanging under the boom, should be mounted on top

of the sliding mechanism.

|

Top right is a squeezable grip (with a yellow highlight drawn

alongside it) used to adjust the tilt angle of the mike cradle, by

squeezing the grip, which pulls on the red-highlighted control string

(that's pinged-off and gone slack in this photo). You can see

some velcro around the grip, as someone's solution to fix the mike at

a specific angle (there isn't a built-in lock control).

The grip is, also, used to rotate the shaft that it's mounted on

(as per the yellow arrows), to change the rotational angle of the

mike cradle. Which pulls on another string (highlighted with

aqua), to move a small pulley that re-tensions on of the mike cradle

strings.

Just below it is a string coming out the back of the pole

(highlighted with purple) and going around a horizontally mounted

pulley (it's anchored inside to the end of the telescoping section of

the mike boom arm), it goes back and forth a couple of times around

four pulleys (two on the moving section, two at the back near the

horizontal pulley), then anchored at a knurled knob on the moving

section above two of its pulleys. The knurled knob lets you

take up the slack on the control string when initially setting up the

boom

The large counterweight seen at the left of the picture, mounted

under the end of the boom, is in the wrong position. The

smaller fixed counterweight should be attached here, and this large

one should be mounted on top of the sliding section.

|

|

The squarish section with pulleys moves along the back of the pole

as the front telescoping section is extended or withdrawn. It

should have the large fixed counterweight mounted on top of it, and

the variable counterweight mounted under it. As it moves, it

maintains appropriate tension on the drive cords by taking up the

slack as the pole is withdrawn, and the counterweights get

repositioned to counteract the shift in centre-of-balance. Just

above the pulleys are two knurled knobs which can be turned to

initially tension the strings up. The string on the left set

(highlighted wih purple) eventually goes into the back of boom arm,

and to the back of the telescoping section. The string on the

right (highlighted with green) goes around the big drum, and

eventually goes into the middle of the boom arm, where the

telescoping section slides into the fixed section. Together

they telescope the boom arm, and move the counterweight.

Above it is a rotating pole that is twisted (using a squeezable

grip), to rotate the microphone cradle around. Squeezing the

grip changes the angle the microphone is tilted at. At the

right-hand side of the pole is a knurled knob, then a pulley.

The control string (highlighted with aqua) went over the top of the

pulley, going downwards around the outside (the side facing the

camera). This kept popping off until I adjusted the length of

the string. It may be that it's supposed to go under the

pulley, instead. The knurled knob seemed to serve no practical

function.

To the right of it is the large drum with a crank handle, it's

used to wind the extendable portion of the pole in and out. It

has two strings wound around it (several times, for grip). The

inner one (green highlight), is directly attached to the telescoping

section of the pole (for extending or withdrawing it). The

outer one (blue highlight) is the other end of the mike cradle tilt

string, it shortens the tilt string as the telescoping boom arm is

shortened. I don't know why they didn't employ the same

technique for the mike cradle rotator string, instead of having it go

around several pulleys attached to the moving counterweight

section.

|

|

A string (highlighted in blue) can be seen coming down from top

left (from the large drum), going under the smaller pulley on the

left, going over larger the pulley to its right, then going down

alongside the boom pole out of view to the right (it goes to the mike

cradle tilt mechanism). The left pulley is moveable, rotating

around the axis of the right pulley, in an anti-clockwise direction,

on command (highlighted with yellow). As it does so, it

tightens the string, and causes the mike cradle to tilt.

A white string with a red spiral stripe goes along horizontally

near the top of the boom pole (highlighted in red, in this photo),

and is fixed to a pulley behind the tilt string's pulley (nearer to

the pole arm). When this white string is tensioned (by

squeezing the squeezable grip), it swings the moving pulley

clockwise.

The knurled grip has an orange chain going between it and the

pulley that the spiral-striped string goes around. It doesn't

seem to serve a practical purpose.

Just below the spiral-striped string is another string going

horizontally along the pole (highlighted in green). It's

wrapped around the large drum with the crank handle (left of this

photo, out of view), passes through the gap between the pulleys

discussed above, and goes to a pulley in the centre of the

telescoping section, then inside the boom arm. It's one of the

drive strings for making the telescoping section extend and

withdraw.

|

|

Corrections to this photo: The large

counterweight seen hanging under the boom, should be mounted on top

of the sliding mechanism.

|

The large pulleys are for carrying the microphone audio cable

(none mounted, at the time). It comes from the microphone

cradle (clamped in two or three places at the cradle end), passes

over a pulley in the centre of the boom shaft (where the telescoping

section goes into the fixed section), the around the six pulleys at

the rear (the forward set move with the counterweights, keeping

tension on the mike cable as the telescopic boom changes length),

then it drops down through a hole in the platform.

Above them are five smaller pulleys, the string (highlighted with

orange) is hooked onto the tag behind the two pulleys on the moving

section, looped three times around these pulleys, passes along the

boom, over some other pulleys, and is eventually wrapped around the

rotating microphone cradle at the other end of the boom arm. As

the telescoping boom arm extends and withdraws, the moving

counterweight section shifts along the back of the boom arm, taking

its pulleys with it, and taking up the changing length of mike cradle

rotator string. If this string is not correctly laced up, the

mike cradle spins around as the boom arm is telescoped.

The large weight seen here, under the end of the boom arm, should

have been mounted above the moving section, and the smaller weight

should be mounted here.

|

|

The red spiral striped string (highlighted with aqua) coming in

from mid-right and sloping down towards the left, comes from the

squeezable grip (out of view), passes through the gap between the

large pulleys on the right (there are two independent pulleys on the

same axis), and attaches to the front section of the large pulley on

the left (there are two, on the same axis). When the grip is

used to rotate the shaft it's attached to, it tightens this string,

and causes the smaller pulley (left-most in this picture), to rotate

anti-clockwise around the axis of the pulleys just right of it (in

the direction of the yellow arrow).

Just behind that spiral-striped string is another string

(highlighted with orange) that's sloping upwards towards the left, it

goes over the top of the thin large pulley on the right, then over

the top of the large pulley on the left, and under the smaller pulley

that's even further to the left. When the smaller pulley

rotates around the larger pulley, it tensions up this string, and

rotates the mike cradle.

In front of the thin large pulley on the right, mounted on the

same axis, is a fatter pulley for the mike cable to pass over.

These two pulleys spin independently of each other.

|

|

Corrections to this photo: The large

counterweight seen hanging under the boom, should be mounted on top

of the sliding mechanism.

|

The large counterweight seen at the left of the picture, mounted

under the end of the boom, is in the wrong position. The

smaller fixed counterweight should be attached here, and this large

one should be mounted on top of the sliding section.

It's a significant danger point for smacking your head against,

either walking into it, or having it swung into someone, and it could

really do with some padding being fitted over it.

|

Operating the boom

Just some brief notes about using the boom, the mechanics of it, more

than the sound recording aspects of operating a boom:

The boom operator stands on the platform, or sits on the attached

stool, being mindful that the platform is narrow, so you don't step

off the edge of it. It's only possible to swing the boom through a

bit more than 45°, horizontally, before you get into awkward positions, or

mechanical limitations of where the seat is, or run out of platform to

stand on, and you can pan more to the right than to the left. So you

need to plan where you park the entire vehicle, and how you move it

around. You can have a grip push you around while you're booming the

mike, but it's not particularly stable.

The boom arm can angle up and down by a similar amount, a bit less than

45° in total, I'd estimate. There's a stopper limiting upward boom

(though you still need to be mindful about not crashing into overhead

lighting), but doesn't appear to be one in the downward direction, you may

end up with metal hitting metal, or worse, the mike hitting the floor.

There are two independent locks for the boom arm pan and tilt. You

can see the tilt lock, in the above photos, with red gaffer tape around

it. The pan lock is just a bit below, and 45° around the base of the

boom arm's pivot point, facing forward. There's little need for the

pan lock, other than for transportation, but you'll need the tilt lock to

lock the boom into place for extended static shots, if you can't hold the

weight of the boom. Despite being able to vary the amount of lead in

the bottom moving counterweight, I couldn't get the boom to stay balanced

in all configurations of boom length. And that's not something that

you can do on the fly.

There are three counterweights on the arm, two are fixed weights that

are meant to balance the boom arm against its own weight, there's a third

one that you can vary the amount of lead inside it, to compensate for

different microphone weights. Some boom arm models can carry up to a

3 pound (1.36 kg) microphone (that's very

heavy).

It's really meant to be used as a moving boom, not a static microphone

stand. And this particular boom doesn't have enough locks to fix it

into a particular position. You'd have to tie various controls

against something, to hold them in place. Particularly the mike

cradle pan and tilt controls, and maybe the boom crank handle, if it won't

stay where you put it when you let go.

When the locks are released, you'll have both hands on the controls,

left hand on the grip that lets you pan and tilt the mike cradle, by moving

the grip up and down (pan) and/or squeezing it (tilt), and the right hand

on the crank handle to adjust the length of the telescopic boom.

You'll also have to use your left hand to push the entire boom pole around

to pan and tilt the pole. There isn't a convenient spot on the boom

arm to grab it with your right hand, to pan and tilt the boom arm, other

than part of the mike cradle panning bar, and you'd have to let go of the

crank handle to do that (losing the ability to control that aspect of the

boom, and potentially having it slide out of position under its own

weight).

Other than the boom arm pan and tilt locks, there doesn't appear to be

any other locks on this particular model, or they're jammed (there are a

couple of knurled knobs, on the mike cradle pan and tilt mechanics, that

don't appear to do anything practical).

And now a few notes about the recording side of things:

If you're used to using microphones that are in fixed positions, there's

a couple of things that you need to take into account:

When you move a microphone about, you're making your own microphone wind

noise, as you move the mike through the air, rather than the usual problem

of wind blowing across a mike. The wind-noise effect is still the

same, though, either way. So you need a mike that's not that

susceptible to wind noise, or has a wind guard fitted to it, and you need

to be mindful about how fast you move it about.

When you move a mike around, especially on a complex mount, there's the

possiblity of the mount making noises that will get into the mike,

especially if the boom isn't in good condition. Unlike a hand-held

boom, there's a lot of moving parts. So you need to know basic

maintenance of keeping it working order (e.g. keeping

control strings and mike cables under adequate tension at all times), and

being careful and quiet as you operate it.

The usual trend is to use a highly directional mike on the boom, and aim

it carefully at who's speaking. But I've certainly seen studios use

less directional mikes, where the boom is more about being able to get it

close enough to get good sound, particularly if you need to record group

dialogue, and don't want to be swinging the mike back and forth between

each sentence. And for more complicated studio recordings, there'd be

more than one boom, to be able to cover everyone, and the whole set.

You really must wear headphones, so that you can hear what you're doing,

and can take directions over talkback (if needed). For scripted

recordings, it's very helpful to familiarise yourself with the script,

rather than try to learn everything while observing a rehearsal. For

non-scripted recordings, you need to watch everyone who might speak, even

more closely. Looking for clues about someone about to say something,

noticing them breathing in to get a lungful ready for their lines, noticing

someone watching the others and waiting for their turn,

etc.

You need to be aware of not crashing the boom into things on set,

letting it get seen on camera, nor casting shadows. That may mean

going up and over floor-lamps, telescoping back from ceiling lamps as you

go around them, or having to insist on some lighting position changes, boom

position changes, or needing more than one boom.

Because you will probably be behind or beside cameras, and have to reach

over them, you want the platform up high enough that you can reach the boom

pole down to your actors, with plenty of clearance.

While hand-held booming may be more versatile (being able to freely move

about, and having less mechanical contrivances to manage), a mounted boom

really lends itself to doing long continous takes. Hand-holding a boom

for ten minutes straight, or longer, isn't something that I want to do,

especially not all day long.

Some information from a boom operator

More recently, I was contacted by an ex-BBC boom operator, discussing

this page. He had this information to add:

The knurled knob on the little chain mechanism is the mike cradle tilt

lock—when turned it should lock the chain and hence the pulleys on the

tilt string.

The mike cradle pan lock is the knurled knob at the end of the pan/tilt

lever arm bar.

When setting the mike, you lock the pan/tilt lever in a comfortable

position (as if to operate the mike pointing forwards), and then adjust

the three screws in the pan head to actually point the mic forwards.

Then when you unlock it, it should feel comfortable.

The boom should always be front heavy slightly, as it is difficult to

hold it down, but easy to push upon the tilt/pan lever bar (to raise the

boom).

When operating you always have three fingers on the bar, and finger and

thumb on the tilt/pan lever to keep control of the whole arm assembly.

Mike cables are rigged starting at the rear inner pulley, going over on

to the forward inner pulley, and working outwards and the over the pulleys

to the head where there should be a clamp—we then used a thin tail to the

mic itself to keep handling noise to a minimum.

At the rear the dangling cable went to a U type clamp, which was attached

by a keyring device to the casting under the inner pulley block (think there

is a hole drilled there), and pulled tight-ish to tension the cable.

Again this affects the ease of use.

A word of caution, we removed weight during times of inactivity as they

make flats on the inner rollers of the arm assembly!

To anybody at Flinder's Uni working on the Fisher boom

When I finally got the boom to work (almost) properly, I found a number of

things that still needed addressing, but didn't have time to do:

Much of the mike cradle mechanism was tough to move. I think the

plastic rollers for the control strings around the mike cradle need some

serious degunking, they should spin freely, but don't. Likewise with

the surface of those pulleys (where the string goes around), it should be

clean, but wasn't. Also, the various pivot points of the mike cradle

need degunking. And you probably need to degunk the string that

passes around those pulleys, too.

The mike cable clamp is upside down, and should only be used to clamp the

mike cable. The mike cradle rotator string should pass underneath it,

freestanding. There are several mike cable clips missing around the

cradle that need replacing.

Have a look at the J.L. Fisher website, and this particular link for a

brochure for a similar model Fisher boom, and make

some large blow-ups of the mechanism photos.

The mike lead leading from the mike to the boom ought to be very

lightweight and flexible, to avoid transmitting sound from the boom, through

the cable, to the mike. However, running a thin cable down the full

length of the boom has other drawbacks. A solution could be to run a

normal mike lead down the boom, ending with an female XLR held

by the mike cable clamp on the boom arm (clamp the connector, rather than the

cable). Then run a thin pigtail from there to the mike.

For transportation, there are too many free moving parts on the

boom. Since they don't want to lock, and some parts don't seem to have

a locking mechanism, I'd suggest strapping the crank handle (that winds the

boom and moves the sliding mechanism) into place, for transport. And

maybe a shoelace or two around the boom and strings, to stop them getting

pulled out of place.

I'd extend the boom, periodically, and clean off the dust, so there's less

gunk to get in the mechanisms.